Commercial Projects

TEAMWORK FOR YOUR PROJECT

The Port of Hamburg is a crucial and pivotal port for the shipping industry and commercial vessels worldwide, with thousands of ships passing through the port and the river Elbe each year.

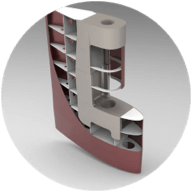

Our NVL shipyard Norderwerft has dedicated facilities for the repair, refitting, conversion, maintenance and servicing of all types of commercial and offshore vessels, including bulk carriers, container ships, reefer ships and RoRos. We feature mechanical, steel pipe, joinery and electrical workshops that are exceptionally well equipped and laid out to optimise material flow, increasing the efficiency for each project.

Our facilities are embedded within a hub of local suppliers and contractors, providing a wide range of quality ship repair support services. The large supplier network also enables our Hamburg shipyards to complete any kind of ship repair project as a ‘one-stop shop’. Commercial vessels can be unloaded, repaired, reloaded and ready to go in just a matter of days, depending on the size of the job.

OUR SERVICES FOR YOUR COMMERCIAL PROJECTS

We offer a variety of services. Although the below list displays a good example of the types of services we can provide, we are of course able to accommodate almost any vessel for any type of repair, even if it is not shown here. For any detailed questions or requirements for your specific project, please don’t hesitate to contact us. We will plan the refit of the vessel in tune with your specific needs.

|

|

|

|

|

|

|

|

|

|

|

|

|

UPGRADE YOUR VESSEL

NO PROJECT IS TOO COMPLEX

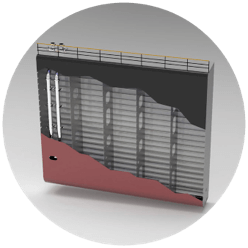

Norderwerft offers engineering expertise and shipbuilding and repair experience in many fields. Also, we are well renowned for special projects. We have earned the reputation that no task is too complex and thrive on the challenges that we are faced with at our shipyards every day. Special projects can range from restoring a historical vessel to its former glory to a complicated lifetime extension for an offshore vessel.

We have been working on floating technology connected with the offshore production and transportation of oil and gas since the 1970s and have therefore gained comprehensive experience with regard to projects of this type. Offshore vessels often operate under very demanding conditions in the far reaches of the world, and the quality of a repair is essential to the safe operation of these vessels. At Norderwerft, work on such units is carried out in line with very high safety standards, operating innovative technology.

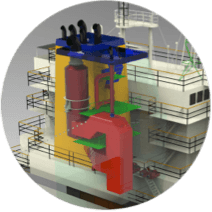

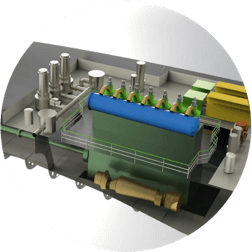

Alongside more conventional, standard repairs to oil/gas offshore units, special projects at both shipyards include the installation of dynamic positioning systems, the performance of structural optimisations, the construction of service cranes, the upgrading of production facilities, the extending of crew quarters and the carrying out of engine repairs.

For such versatile and experienced shipyards, no special project is too difficult. Together, we are capable of realising any project for any vessel.

WORLDWIDE REPAIRS, WHEREVER YOUR SHIP MIGHT BE

We are always close to our customers with a dedicated team of flying squads. No matter where your ship is located, whether it is located in Hamburg or halfway across the world, you can rely on us to deliver global ship services anywhere. Shipping companies can rely on these teams to supply the necessary solutions, including carrying out the ship repairs on location.

No matter if the job is to exchange a small part or involves the handling of a more complicated technical project, teams are as committed to maintaining the same high level of service as when the refit takes place in our own shipyards and docks. The conscientious worldwide ship services team has extensive experience in the maritime engineering industry. They take care of every detail, ensuring projects are completed on time and within budget. Please don’t hesitate to contact us for more information.

REFERENCES

Get an insight and learn some key facts of our projects here.